Automatic Liquid Purified Drinking Water Mineral Water Pure Water Production Line Washing Filling Capping Machine

Product Description Washing, Filling and Capping 3 in 1 Monoblock Drink Water Filling Machine For PET Bottle General des

Description

Basic Info

| Model NO. | CGF18-18-6 |

| Filling Principle | Atmospheric Pressure |

| Packaging Container Lifting Structure | Pneumatic Lifting |

| Structure | Rotary |

| Packaging | Bottle |

| Packaging Material | Plastic |

| Capacity | 5000bph According to 500ml Bottle |

| Power | 3.5kw |

| Weight | 3000kg |

| Air Consumption | 0.8m3/Min |

| Transport Package | Wooden Package |

| Specification | 2300*2000*2300mm |

| Trademark | KLD |

| Origin | China |

| HS Code | 8422301090 |

| Production Capacity | 300 |

Product Description

Product Description

Washing, Filling and Capping 3 in 1 Monoblock Drink Water Filling Machine For PET BottleGeneral description

3-in-1 filling machine, combined with rinsing, filling and capping. It is used for mineral water, pure water, and other drinking water filling in PET bottles ranges from 250ml-2.5L, and capacity from 2000-3000BPH.

Main features

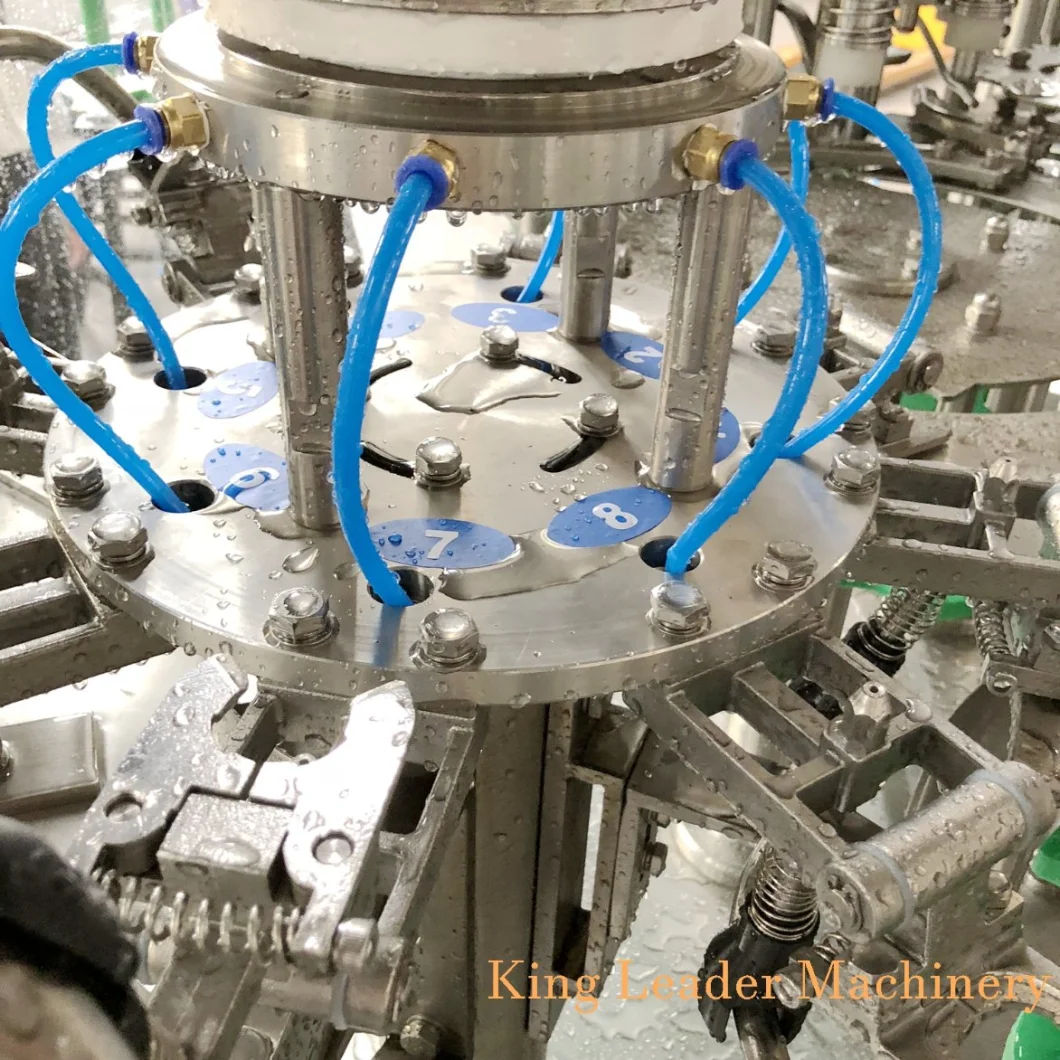

1. Rinsing Part

Spring cramps are used in the bottle washing process. The empty bottles can be turned over 180° Along the conveying rail. There are two times of internal and external washing, the efficiency of bottle washing is high.

Rinsing machine adopts Sunswell original oVERTUrn and double-opened bottle clip. Bottle clip lock the bottleneck, the material of bottle clip is SUS304, which is hygienic and durable.

Bottle clip equipped with efficient spray on nozzle. The extrusive droplet with 15° Angle ensures to wash all side of the bottle, and can save the water.

Made of stainless steel of superior quality.

Equipped with bottle jam protection device.

Picture of Rinsing Part

2. Filling Part

The design of filling structure is reasonable and hygiene dead angle, the run of equipment is stable, it can control the material from the bottleneck, the control accuracy is within ± 2mm (subject to bottle design). The filling valve material is SUS304. The filling system has liquid level automatic control. Filling valve lift is controlled by the valve elevator, after filling valve contact the bottleneck, it start to fill. Bottle is conveying by the wheel in the filling part.

Picture of Filling Part

3. Capping Parts

Screw capping machine is most precision part in the 3-1 machine, it has a big influence to the goods stability and defective rate. Our screw capping has following feature.

Picture of capping Part

Electrical configuration

| Name | Brand |

| PLC | MITSUBISHI |

| Touch Screen | MITSUBISHI |

| Transducer | MITSUBISHI |

| Contactor | SCHNEIDER |

| Pneumatic Parts | AIRTAC |

Technical parametersModel: CGF18-18-6Amount of working position: Rinsing 18, filling 18, capping 6Production capacity:5000BPH*500mlPressure of air source: 0. 7MpaAir consumption: 0.25m3/minPressure of rinse water: 0.2~0. 25MPaConsumption of rinsing water: 1t/hour (can be adjusted)Filling pressure: 0.2-0.3MpaSuitable bottle size: H: 150-300mm, D: Φ50-110mmTotal power: 3. 5KWWeight: 3000kg

Next: Customized Small Beer /Carbonated Drink Beverage Filling Packing Labeling Machine for Glass Bottle

Our Contact

Send now