Liquid Online-Service Paixie Automatic Bottle Alcoholic Beverage Whisky Aseptic Food Oil Wine Machinery Filling

Description

Basic Info

| Model NO. | PX-BFC80 |

| Automatic Grade | Automatic |

| Material Type | Liquid |

| Filling Valve Head | Multi-Head |

| Feed Cylinder Structure | Multi-Room Feeding |

| Dosing Device | Plunger |

| Filling Principle | Pressure |

| Packaging Container Lifting Structure | Pneumatic Lifting |

| Structure | Linear |

| Packaging | Bottle |

| Packaging Material | Metal |

| Drive | Servo System |

| HMI | 7.5” Color Touch Screen Control |

| Protection | Comprehensive Safety Alarm System |

| Detecting System | Vial Detector & Counter |

| Transport Package | Non-Fumigation Wooden Box |

| Specification | 1200*900*2200mm |

| Trademark | PAIXIE |

| Origin | Shanghai China |

| HS Code | 8422301090 |

| Production Capacity | 2000 Bph |

Packaging & Delivery

Package size per unit product 1200.00cm * 800.00cm * 750.00cm Gross weight per unit product 400.000kgProduct Description

Product Description

Product Parameters

| Model | PX-18-18-6 | PX-18-18-6 | PX-32-32-8 | PX-40-40-10 |

| Productivity (500ml/H) | 3000-6000 | 6000-7000 | 8000-11000 | 11000-13000 |

| Filling temperature (°C) | 5 | 5 | 5 | 5 |

| Filling pressure (MPa) | 0.2-0.35 | 0.2-0.35 | 0.2-0.35 | 0.2-0.35 |

| Power (Kw) | 5 | 6 | 8 | 12 |

| Overall dimension (m) | 2450*1700*2300 | 2450*1700*2300 | 4400*2000*2300 | 4400*2000*2300 |

| Weight (kg) | 4000 | 5000 | 6000 | 9000 |

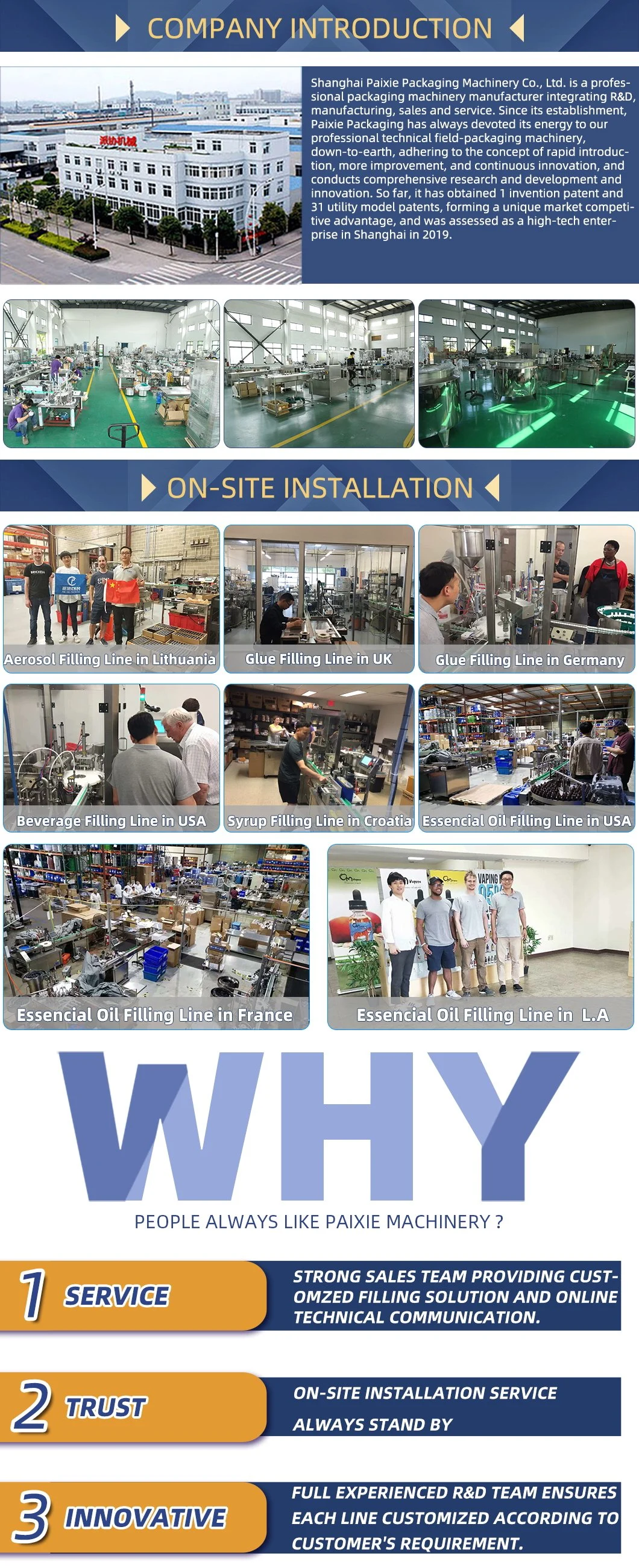

To look how PAIXIE boys do

Compared with tradtional machinery , PAIXIE smart filler has below characters which are benefited to each customer operation experience :

1- With servo driving , operator just edit the filling parameter on HMI to realize all kinds products packing .

2- 150mm width SS304 protection frame which equied with induction switch is able to stop machine whenever operator open the plexiglass door which is good for human protection .3- PAIXIE'S machines are all equiped with scale rules for diffeferent kinds bottle replacing , which is convenient for date recording and save the time in adjusting .4- All PAIXIE'S machine are made of SS304+SS316 which avoiding pollution perfectly , protect custoomer's product quality . 5- Machines are deliveried as whole which solving the stress of after sell installation for customer . PAIXIE'S technicians are standing by all time for on-site service .

Real machine factory scene

1. Enhanced food safety: Stainless steel 304/316L for all components in contact with your beverage2. Optimum uptime: 30 % reduction in changeover and maintenance downtime3. Sustainable solution: Reduced filler enclosure and servomotors reduce resource consumption4. Hygiene improvement through volume control and contactless fillingFilling station

1. 304/316 Stainless steel high precision filling nozzle

2. Filling volume adjustable in fine rank, same liquid level after filling

3. All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

4. 304/316 stainless steel filling pump

5. Efficient spray nozzle rinse thoroughly and save water for flushingCapping station

1.All parts in contact with liquid are made of high-quality stainless steel materials or food-grade engineering plastics, which meet the national food hygiene standards.

2.The bottle bottom support plate of the bottle output wheel adopts a spiral descending method, and the height of the bottle conveyor chain is not required to change the bottle shape.

WHY people like PAIXIE ?

You may be warrying those ?

1- How can i fill so many formats my bottles with the machine perfectly withour complex adjusment ?

2- How can i understand your quality ?I do not want any kinds bad machine which failed to live up to my investment .

3- How can i know your machine life ? It looks always beautiful but only in your room .

4- How can i install such a big long machine by myself ? It looks never eaasy at all .

5- How can i recognize the real difference in chinese market ? So many suppliers quoted me every day !!!

6- What can i do if machines get broken in broken ? Who is gona to help me ?

Our Contact