Sauce/Juice/ Soap Water/Tomato Paste/Cream/Ketchup/Fruit Jam/Beverage/Peanut Butter/ Shampoo/Oil/Honey/Liquid Sachet Filling Package Packaging Packing Machine

Sauce/Juice/ Soap Water/Tomato Paste/Cream/Ketchup/Fruit Jam/Beverage/Peanut Butter/ Shampoo/Oil/Honey/Liquid Sachet Fil

Description

Basic Info

| Model NO. | DXDL-240 |

| After-sales Service | Online Support |

| Warranty | One Year |

| Automatic Grade | Automatic |

| Application | Cleaning, Detergent, Drinks, Skin Care Products, Dairy Products, Hair Care Products, Oil, Tea, Vegetable, Fruit, Fish, Meat, Snack, Seasoning |

| Type | Forming Filling Sealing Machine |

| Forming Species | Bag Moulding |

| Forming Function | Forming, Filling, Seal |

| Driven Type | Electric |

| Material Type | Liquid |

| Packaging | Bag |

| Packaging Material | Film |

| Transport Package | Wooden Box |

| Specification | (L*W*H)630*750*1600mm or 1000*750*1700mm |

| Trademark | Huihe |

| Origin | Shanghai, China |

| HS Code | 8422303090 |

Product Description

Sauce/Juice/ Soap Water/Tomato Paste/Cream/Ketchup/Fruit Jam/Beverage/Peanut Butter/ Shampoo/Oil/Honey/Liquid Sachet Filling Package Packaging Packing MachineFeatures

1. With the function auto filling, measuring, bag forming, sealing and cutting.

2. Bag-making system adopts step motor with high precision (error is less than 1mm).

3. Controller adopts Chinese or English displaying, can see the working conditions directly.

4. Heating sealer with 4 sides of heating control, each sealing side temperature can be adjusted separately with good heat-balance to ensure the seal in good quality, suit for a variety of packaging materials.

5. With intelligent photoelectric controller system.

6. Good visibility with side-open protective platens, operate safely.

7. Adopt the newest hopper sets, easy to adjust and clean, no need adjust again after clean, so that can improve working efficiency

8. This machine is suitable for the packing of liquid/paste/sauce products, bag can choose from 3-side, 4-side or back side seal according to customer needs.

9. Ribbon printer is addable according to customer needs, which can print one to three lines letter, date of produce and batch number.

10. Packing material: composite film such as (PET/PE), (Paper/PE), (PET/AL/PE), (OPP/PE), etc.

Specification

| Model | DXDL-240 | DXDL-300 |

| Bag Type | 3 or 4 sides seal | back side seal |

| Bag Size | W: 30-120mm L:30-170mm | W: 30-140mm L:30-170mm |

| Packing Speed | 20-60 bag/min | 20-60 bag/min |

| Method of Measurement | piston pump type | piston pump type |

| Range of Measurement | 0-100ml | 0-150ml |

| Total Power | 1400W | 1600W |

| Machine Weight | 200kg | 260kg |

| Machine Size (L*W*H) | 630*750*1600mm | 1000*750*1700mm |

| Voltage | 380V or 220V or made accordingly | 380V or 220V or made accordingly |

Application

This machine is suit for small sachet packaging of liquid/paste/sauce products such as water/oil/peanut butter/paste/sauce/ketchup/honey/salad/soup/juice/milk/shampoo, etc.

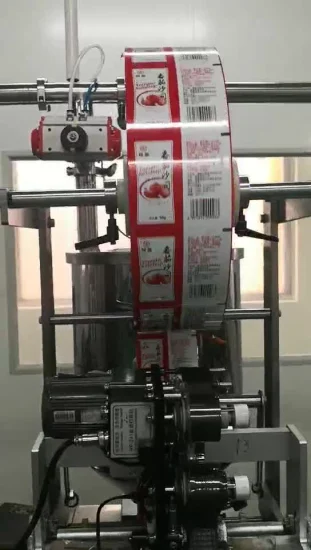

Machine pictures

Our packing samples

Our machines are working in our customers' factory

Payment terms

Choose the machine type → Goods delivery :(FOB,CIF,CFR,EXW) → Payment term :30% down payment as for ordering the machine (or 100 % payment that can save time ) → Confirmed the machine requirement → Based on your requested to producing machine→ Though video chat or send machine picture or directly come to inspection in our factory → Pay the rest of balance 70% → Arrange the shipment .(If need more technical support ,please contact our services )

After Sales Service

1.Guaranty: One Year.

2.One set of consumable accessories will be provided with the machine.

3.Any question, you can mail/call us at any time. And our most experienced engineers are assigned to give consulting service, and always available for dispatching abroad.

4.All spare parts are always available for delivery.

5.Manual is in English.

Installation/Training

If really don't know how to install and operate after showing the video and telephone instruction, you can ask for installation from us. It must be after shipment till the machine has arrived and factory must be ready equipped with all necessary requirements before booking installation. Our engineers will come to the site for the complete and final installation. During the installation session, a training course will be provided to our customers about operation and maintenance procedure. The following costs should be paid by the buyer, including engineer's all local transportation, accommodation, and air tickets (round trip).

Welcome to our factoryPart of our Customers

Our Certificate

Prev: Automatic Bottle Jar Pail Liquid Butter Sauce Tomato Paste Filling Machine with Sealing Capping Line

Our Contact

Send now