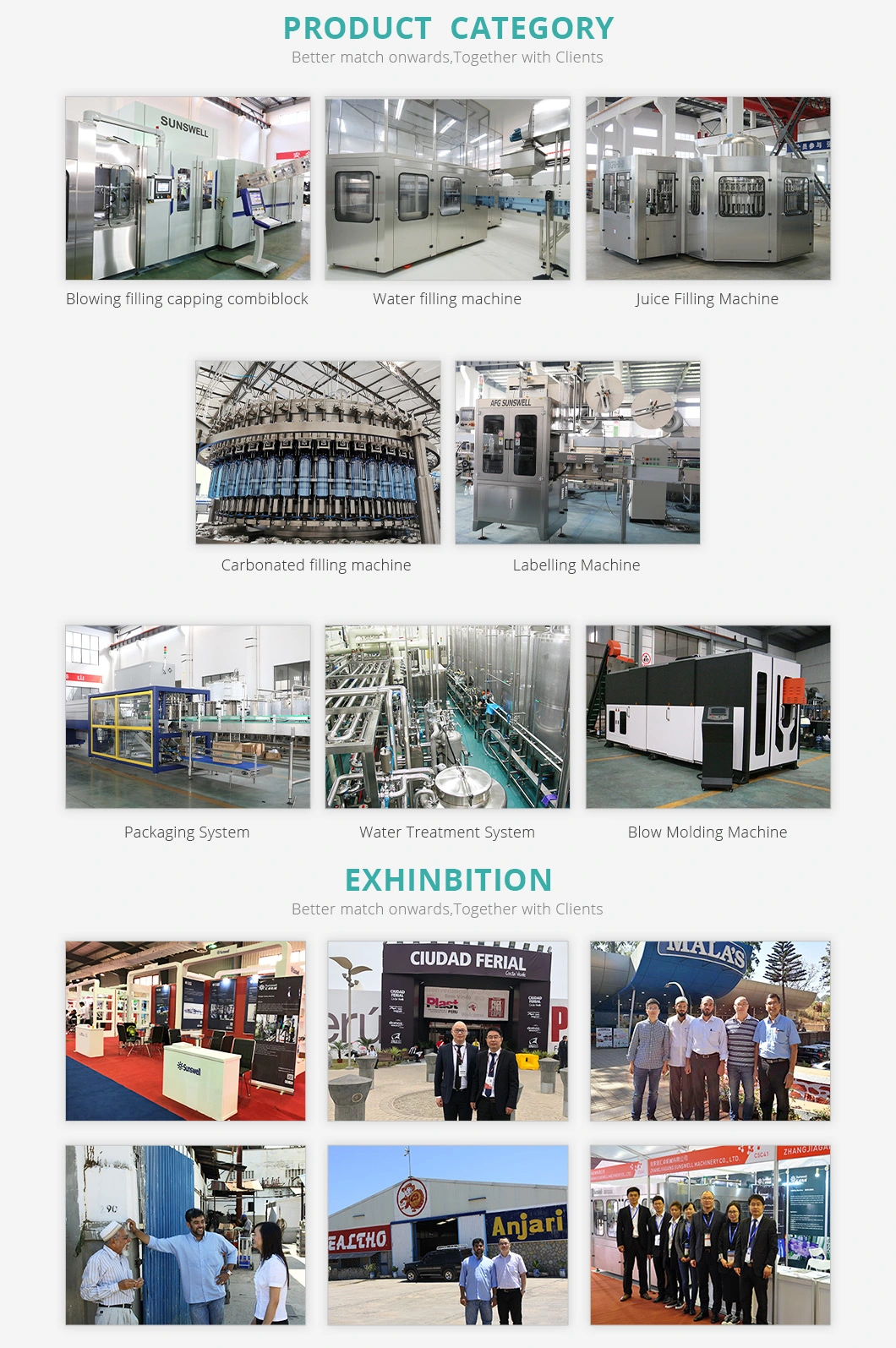

Soft Drinks Can Filler and Seamer

Description

Basic Info

| Model NO. | Soft drinks can filler and seamer |

| Feed Cylinder Structure | Single-Room Feeding |

| Dosing Device | Surface Type |

| Filling Principle | Negative Pressure |

| Packaging Container Lifting Structure | Pneumatic Lifting |

| Structure | Rotary |

| Packaging | Can |

| Packaging Material | Aluminum Can |

| Machinery | Soft Drinks Can Filler and Seamer |

| Function | Filler, Filling, Seamer, Seaming |

| Usage | Beer, Carbonated Soft Drinks, Cola, Gas Water |

| Packing Container | Aluminum Can, Plastic Can |

| Capacity | 2000cans-20000cans Per Hour |

| Transport Package | Film Wrapping Plus Wooden Case |

| Specification | 2200X2100X2200MM |

| Trademark | SUNSWELL |

| Origin | China |

| HS Code | 8422301090 |

| Production Capacity | 2000-20000cans Per Hour |

Product Description

Soft drinks can filler and seamer

It is suitable for filling and sealing aluminum canned beer and carbonated soft drinks. It is equipped the advanced device, electrical equipment, and pneumatic control technology. It has the characteristics of filling reposefully, high speed, liquid level control, capping reliably, frequency conversion timing, less material loss. It can be equipped long-distance control system. It is the preferred equipment for the medium beer and beverage plant.

Working procedure

Can is pushed into can holding platform one by one by feeding screw and star-wheel. After flushing by CO2, centering cup of filling valve will fall to can; the distance between filling valves and cans are sealed by springiness plastic ring. The movement of centering cup is generated by plastic idler wheel along curvilinear motion. After filled, valve will be closed, air is discharged, and centering cup will rise from the can. Filled can will be sent to conveyor chain, then to capper. Seamer will take the lid, turn over the edge of can and turn the edge to finish the sealing action by the control of cam. High pressure foam flushing device is equipped. After that can is transferred to conveying system.

Main features

1) Wholly sealed widow structure which is beautiful, concise, easy and highly operated;

2) Cycling tank design with precision polishing inside;

3) High precision and large flow rate filling valves to meet productive requirement;

4) Specially designed roller structure which is easy to be adjusted, locked and ensure sealing function;

5) Friendly and convenient operating panel with high expansibility.

6) The filling valve is adopts high precision mechanism valve, fast speed filling, high precision liquid level.

7) The filling vat adopts 316L material designed sealing vat, to achieve constant pressure filling.

8) The flow rate of the filling valve>125ml/s.

9) Main transmission adopts toothed belt and gearbox open-type transmission assemblies, high efficiency, low noise.

10) The main drive adopts step-less speed change for frequency conversion, the whole machine adopts PLC control; the capping machine and filling machine adopt coupling joint, to ensure synchronization of two machines.

11) With filling with can, no filling without can.

12) The filling manner is constant pressure filling, with fast filling speed and stable action.

13) Adopting introduce into full set of Switzerland (Ferrum) capping technology.

14) Capping trolley adopts high hardness alloy steel quench(HRC>62), capping curve adopts projection grinder precision machining, to ensure the quality of capping.

15) With capping with can, no capping without can control system, to ensure the normal running of the machine.

16) With CIP automatic rinsing function.

17) With centralized lubrication system.

For more information of the Soft drinks can filler and seamer ,pls feel free contact :

| Sales Manager | Jessi |

| Telephone | 0086 512 5850 1665 |

Next: Automatic Cans Sealing Machine/Automatic Cans Seamer /Big Size Suitable for Big Cups/Cans/Bowls

Our Contact