GS-T113h High Speed Automatic Labeling Machine for Flat Sticker

Description

Basic Info

| Driven Type | Pneumatic |

| Classification | Automatic Vertical Round Bottle Labeling Machine |

| Packaging Material | Film |

| Packaging | Cartons |

| Voltage | 110V/220V/380V |

| Certification | CE Certificate |

| Machinery Capacity | 0~120 M/Min |

| Machinery Test Report | Provided |

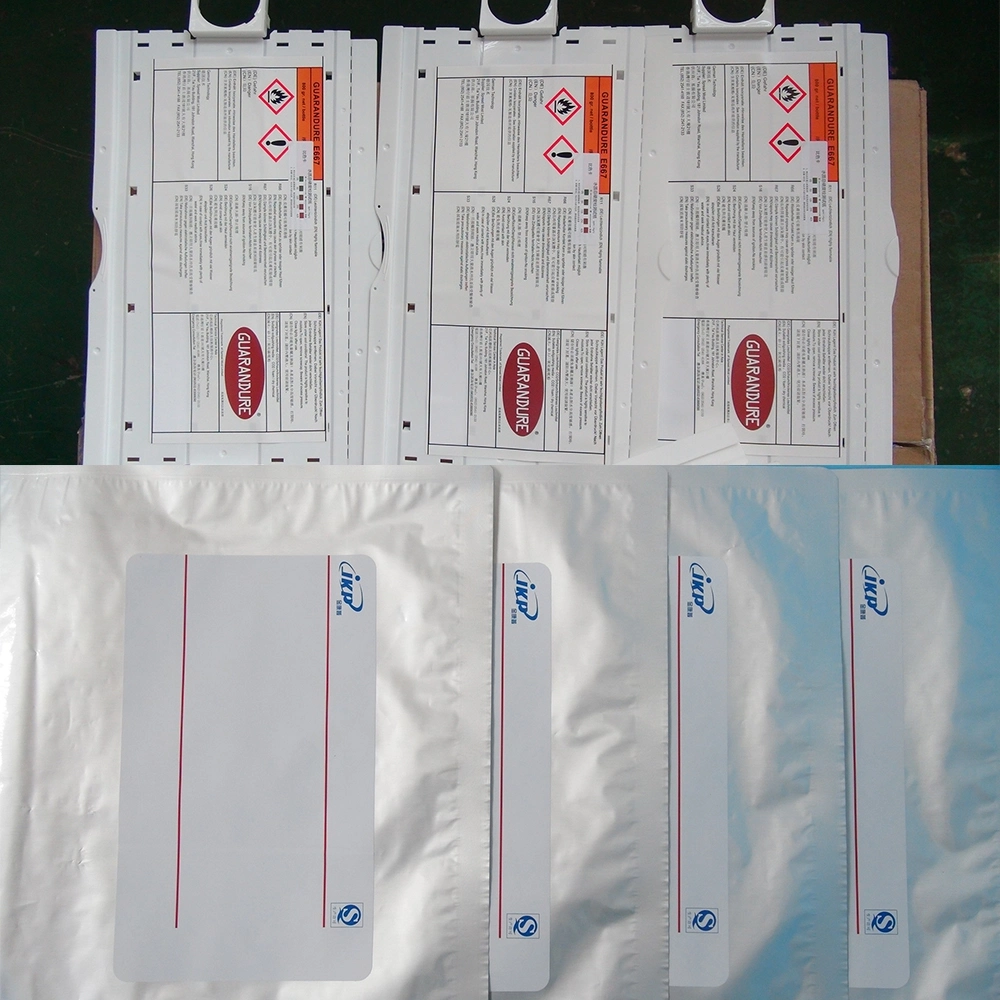

| Label Material | Plastic and Film |

| Bottle Type | Box / Carton |

| Applicable Product Size | L 20~500mm, W 20~300mm |

| Label Length | 10~100 mm |

| Label Width | 20~250 mm |

| Keyword | Vial Labeling Machine |

| Core Components | PLC, Gear, Motor, Gearbox |

| Bottle Material | Glass Metal Plastic |

| Labeling Accuracy | ± 1 mm |

| Transport Package | 2050(L)*650(W)*1450(H)(mm) |

| Specification | 105 |

| Trademark | Gosunm |

| Origin | China |

| Production Capacity | 100 Set/Sets Per Month |

Product Description

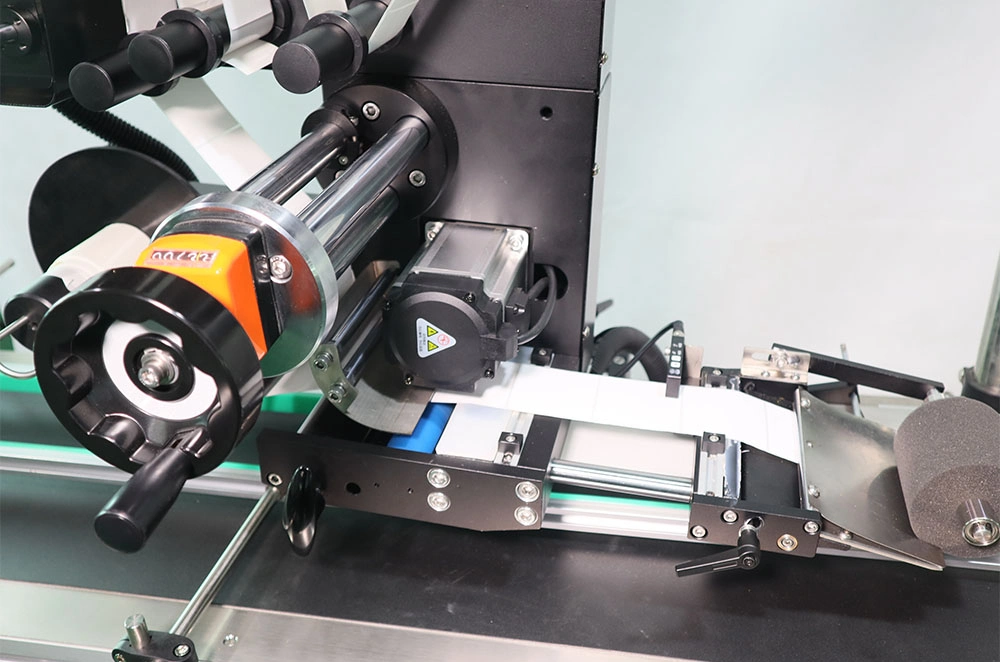

GS-T113h High Speed Automatic Labeling Machine for Flat Sticker

Product Name | Sticker Flat Labeling Machine |

Model | GS-T113H |

Size(mm) | L 1600 W*900 H*1500mm |

Weight (kg) | 105 |

Voltage/Frequency | 220V/380V / 50HZ |

Applicable label length(mm) | 10~150 |

Applicable label width(mm) | 10~100 |

Applicable product size(mm) | L 20~500mm W 20~300 |

Labeling accuracy | ±1 |

Labeling speed(pcs/min) | 30~200 |

Self-adhesive label parameters:

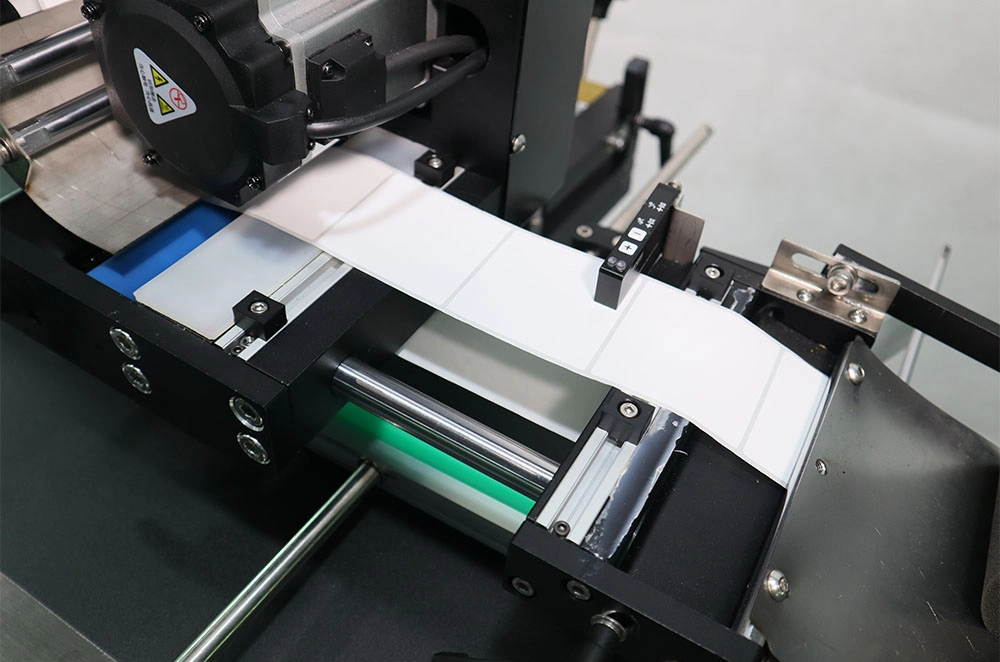

Roll label in the labeling machine work the entire process, including label delivery, positioning, out of the label, paste and backing paper re-roll, to successfully complete the labeling process, the overall label has the following requirements. Label spacing: 3-4mm ± 0.2mm, the upper and lower edge of the label and the bottom of the backing paper spacing: 2mm Surface material: basic grammage 78 g/m2 plus or minus 10% Thickness: 0.064mm plus or minus 10% Backing paper: Basic weight 61g/m2 plus or minus 10% Thickness: 0.055mm plus or minus 10% Consistent release force, uniform thickness, a certain tensile strength, translucent Grassian base paper is generally between 60-80 g, fiber density tightness flatness to be good, not easy to break when labeling, the overall translucency to be consistent, the sensor correctly identify the location of the label. Tensile force: machine direction: 16kg/25mm Horizontal direction: 7kg/25mm Tear resistance: machine direction: 25g / sheet Crosswise: 31g/sheet Before labeling to eliminate the static electricity in the roll label, so that the label is firm out of the label, from the backing paper, because static electricity will cause labeling when not out of the label or the labeling inaccuracy phenomenon, die-cutting to avoid cutting through the backing paper and not out of the label and torn backing paper phenomenon.

Company Profile

FAQ

1

Q: Are you a factory or trading company?

A: We are a factory which license of import & export.2

Q: Where is your factory located? How can I visit there?

A: Our factory is located in Dongguan City,Guangdong province China.The nearest airport is Shenzhen airport(30mins driving).We would like to pick up you in that airport. Welcome to visit us!3

Q: How long is the warranty period ?

A: Perfect after-sales service, one year machine warranty, free replacement of accessories.4

Q: How about the installation? Do you have after-sale service?

A: We will send professional technician to your company to install the machine and train your staff until they could operate the machine independently. 5

Q:How long we will get the machine?

A: Delivery time up machine machine model, standard machine normally can shipping out within 10days, special machine up to our PI confirmed delivery date. And after shipping you just need wait the ship container arrived to you. 6

Q: Why should we choose your company?>Certified company with CE certificates.>Machinery and equipment professional manufacturer for 13 years, with more than 130 advanced patents.>Chinese, English, and Korean languages manual, and we provide a complete machine assemble video. After-sales engineers are available at 24 hours on line.

>The machines are sold overseas and we have agencies in many countries, which can provide on-site installation, commissioning and maintenance services.

Prev: Hzpk China Pet Can vacuum Sealing Machine Can Seamer

Next: 4515 L-Stype Sealing and Shrinking Packaging Machine Automatic L Bar Sealer and Heat Shrink Tunnel

Our Contact