Automatic Single-Dose Liquid Perfume Plastic Ampoule Filling Machine Ggs-118

Description

Basic Info

| Model NO. | GGS-118 (P5) |

| Certification | CE, GMP, ISO |

| Voltage | 220V |

| Computerized | Computerized |

| Customized | Customized |

| Condition | New |

| Warranty | 1 Year |

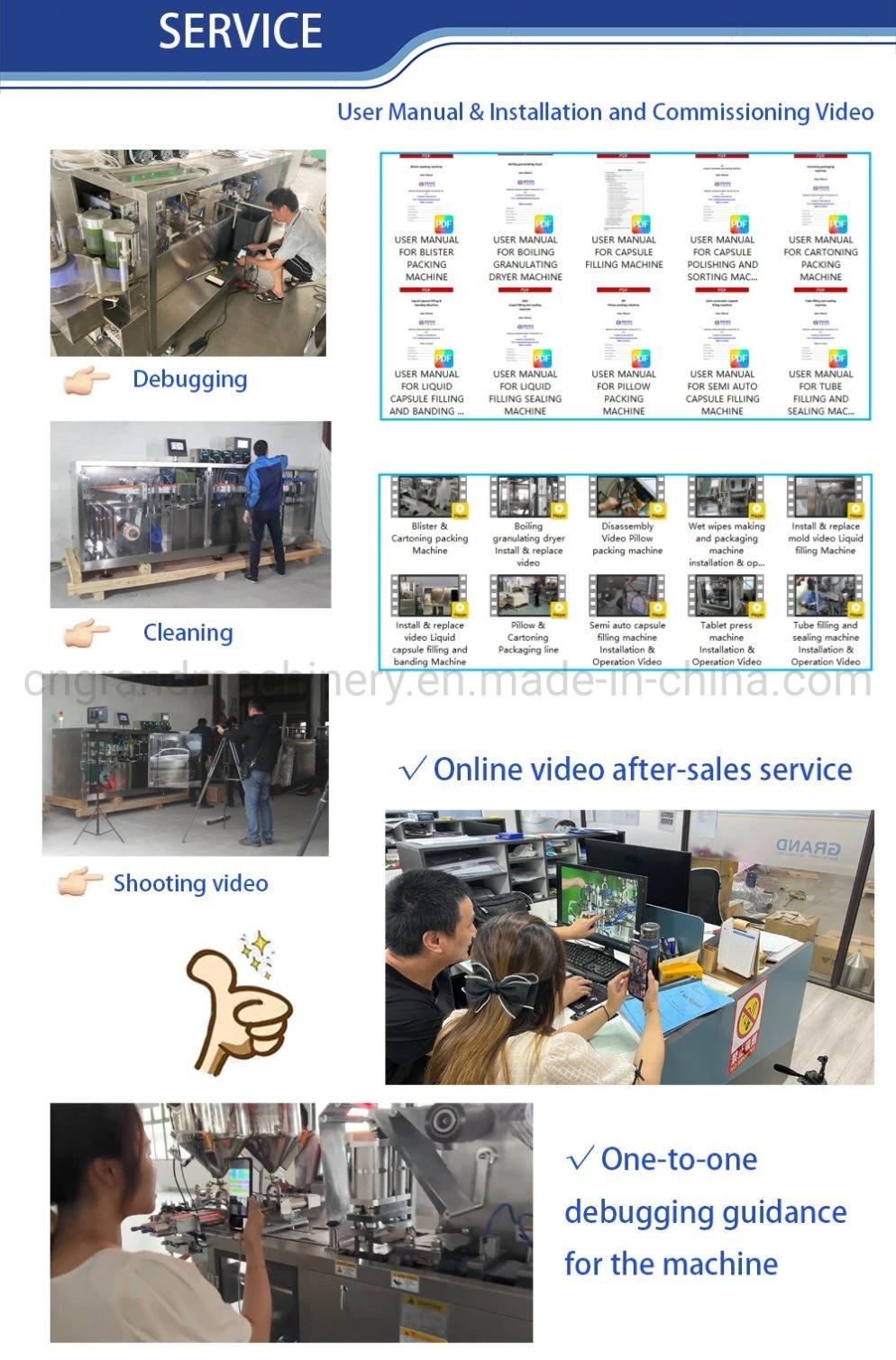

| After-sales Service | Video Technical Guidance |

| Name | Single-Dose Ampoule Packing Machine |

| Pump | Peristaltic Pump |

| Application | Liquid Perfume Filling and Sealing |

| Applicable Material Film | Pet/PE and PVC/PE |

| Transport Package | Wooden Box |

| Specification | 2300mm (L) x 850mm(W) x 1400mm(H) |

| Trademark | GRAND |

| Origin | China |

| HS Code | 8422303090 |

| Production Capacity | 50+ PCS\Min |

Packaging & Delivery

Package size per unit product 2300.00cm * 850.00cm * 1400.00cm Gross weight per unit product 900.000kgProduct Description

GGS Series Liquid Filling And Sealing Machine

APPLICATION:

This machine is a kind of small plastic bottle thermoforming filling & sealing equipment,it's suitable for small batch filling in pharmacy,pesticide,cosmetic,food & beverage and nutrition etc. Field for liquid & Cream material,it's widely used for filling oral liquid,liquid pesticide & fertilizer,E-Liquid,liquid & Cream cosmetic,edible oil,beverage and liquid health care product etc.

Sample Pictures Of The Liquid Filling And Sealing Machine

Stand-up bottle, tomato paste, pesticide, Physiological saline, juice, edible oil, olive oil, Small bottle filling for syrup, honey, jam small bottle filling cosmetics, skin care products vial filling curcumin, liquid pesticides, etc.

A set of molds are attached to the machine, and free custom drawings. Click me to consult how to get the mold design plan.

Detailed Photos

1. The machine adopt PLC control and stepless altering frequency adjustment.

2. The machine can finish the following working procedure automatically through the program: PVC Roller release ,PVC Preheating ,bottle forming ,filling,end sealing & batch number ,perforation & end Punching and Cutting.

3. The machine adopt the human-machine interface operation, operation is easy and simple.

4. The filling head has no leak through ,not appear foam and overflow.

5. The contact parts with the filled liquid adopt SUS316L, conforms to the GMP standard.

6. The main pneumatic component and electric parts adopt well-known brand products.

7. Filling system can choose peristaltic pump, piston pump, rotary valve pump according to different filling material, measuring is precisely and the filling difference is small.

Sample showcase

Product Parameters

| Model | GGS-118 P5 Liquid Ampoule/Vial Forming Filling Sealing Packing Machine |

| Max.forming depth | 12 mm |

| Forming frequency | 0-25 times |

| Packing material | PVC/PE,PET/PE(0.2-0.4)*140mm |

| Filling volume | 1-50 ml |

| Total power supply | 7 kw |

| Voltage | 220-380V/50Hz |

| Machine weight | 900 Kg |

| Overall dimension(L*W*H) | 2300*850*1400(mm) |

Click here to start chatting.Welcome to consult for solutions.

Similar Products

| Cartoning Machine | Blister Packing Machine | Liquid/Oil Capsule Filling And Sealing Machine |

Certifications

About our company:

Wenzhou Grand Machinery Technology Co., ltd. was established in 1999 by several experienced machinery experts, located in Wenzhou City, Zhejiang Province, China. Grand is specialized in R&D, manufacturing, exporting and providing related services of pharmaceutical equipment in solid preparation field. Main products include grinder, granulator, dryer, mixer, capsule filling machine, tablet press, blister packing machine, bottle filling line, cartooning and encasing machine.Grand has over 5,000 meters standard producing plant and modern office, with more than 85 staff consisting of efficient producing team, experienced R&D team, professional sales team and thoughtful after sale team.Grand has passed the certification of ISO9001 and products have CE certification approved.

Our Advantages

1.We are a factory enterprise, more convenient to meet customer requirements.

2.High production capacity, leading technology.3.We can provide capsule polishing machine, granule counting machine, etc. which are matched with the machine, so as to meet more needs of customers.4.Our factory has a price advantage and is close to the port.5.Customers do not have to worry about after-sales problems, we will provide installation and technical support at any time.

FAQ

(1).Are we a factory or a trading company?

- We are an enterprise integrating industry and trade.

(2).Where is your factory? How can I visit your factory?

- Our factory is located In Rui'an Zhejiang province. We are warmly welcome you visit our Factory if you have a travel plan.

(3).How can you know if our machine is suitable for your production requirements?

- You can tell us your requirements and send us the sample pictures and videos. If possible, it is best to send samples to us for machine debugging.

(4).We are cooperating for the first time, and you are afraid of risks.

- You can check our business license, etc. All the information we show is true. If you still have concerns, we can trade on the website, which protects the rights and interests of both parties.

(5).What are the payment methods?

- For small testing orders,we accept Paypal,Western Union,T/T and credit Card. For mass orders,we accept T/T and L/C.

(6).How do we contact you?- Please leave a message and click "send" to send us an inquiry.

Prev: Semi-Automatic Pet Bottle Sleeve Film Shrink Packing Machine (YCTD)

Next: Npack Servo Automatic Diesel Engine Lube Lubricant Bucket Gallon Oil Jerrycan Filling Machines

Our Contact